Noise- and also Vibration-Sensitive Sites: Why Micropiles and Helical Piles Excel

No one whines regarding a silent jobsite. They whine when the anchors shake a NICU airfoil, when a commuter rail line sheds its track alignment due to the fact that a contractor resonated the subgrade, or even when a famous stonework façade picks up hairline fractures from percussive job. On medical facilities, records facilities, galleries, laboratories, broadcast studios, and structures with fragile finishes or maturing fabric, sound as well as resonance are actually certainly not problems, they are venture awesomes. That is where micropiles as well as helical piles get their keep.

I have placed each bodies in to limited basements, under active operating table, via filler no person relied on, as well as along urban gathering wall structures where next-door neighbors determined sound with their very own meters. The devices are actually small, the strategies effective, and the ground disorder slight. Effectiveness depends upon comprehending how each system behaves, what equipment you can in fact fit via the door, and also exactly how to tune setup to the site's tolerance for resonance and sound.

Why resonance command determines the structure strategy

Vibration is actually not a single variety. Taken up health care spaces often ask for peak bit speed under 0.12 in/s in nearby places for vulnerable devices, occasionally lesser near MRI collections. Galleries as well as repositories might prepare stringent limitations to protect vulnerable assortments. Rail agencies commonly need continuous resonance tracking with alarm system thresholds on online paths. In mixed-use properties, our company work all around long quiet windows and also limit work to daytime hours. These restraints remove very most driven possibilities and typically bring in large-diameter drilled arrows not practical, especially in low headroom.

Micropiles and also helical piles traversed these restrictions due to the fact that they put up with rotating torque as opposed to effect power. Instead of hammering, we turn. As opposed to a crane, our team turn in along with small gears. As well as instead of spoils by the truckload, our team record limited returns or none in all. The business is simple: more aspects of much smaller dimension, designed to higher device sizes by means of steel effectiveness and bond stress.

The makeup of a peaceful foundation

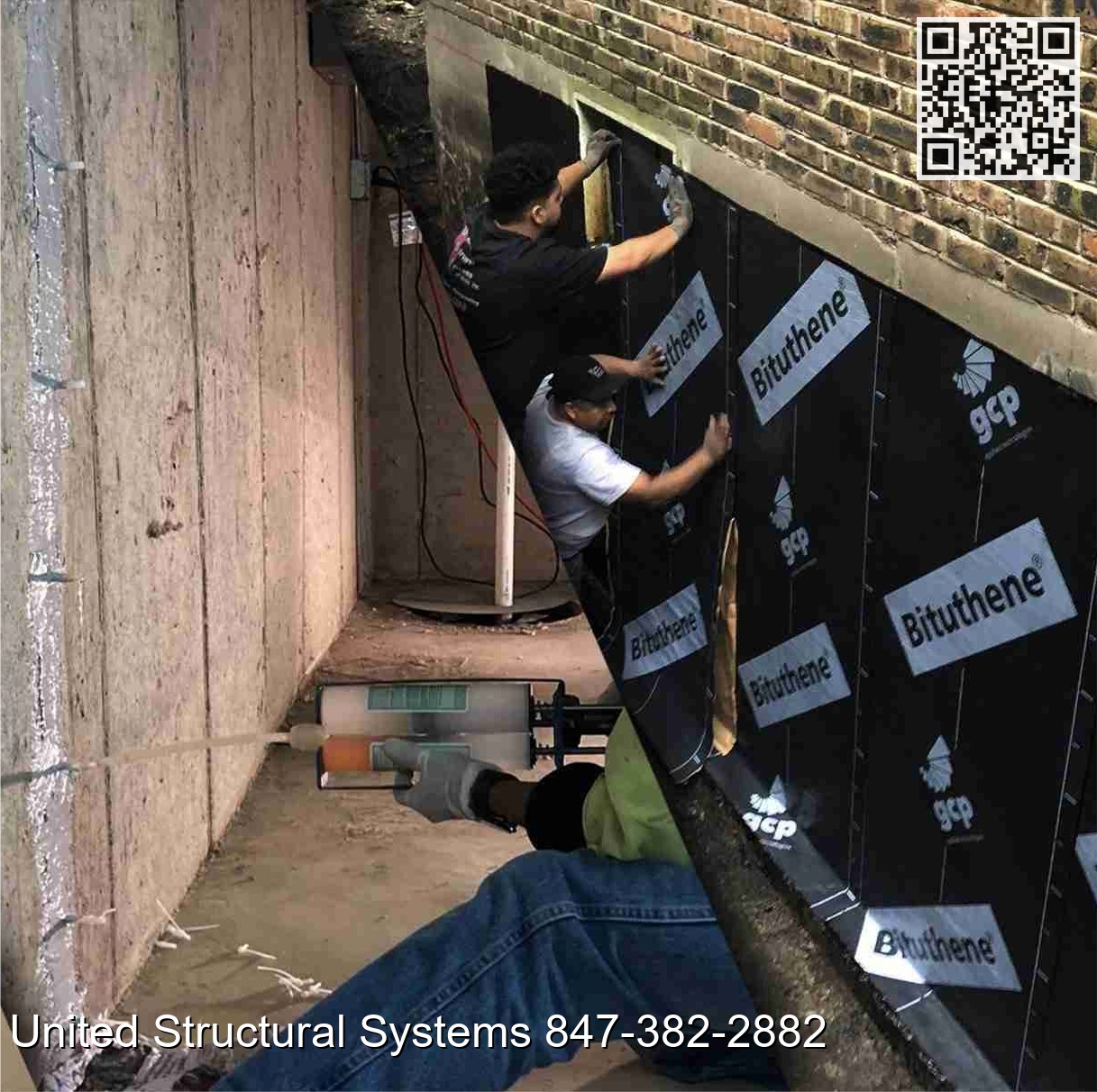

On a noise- as well as vibration-sensitive site, every activity is determined: mobilization, set up, exploration or accelerating, grouting if applicable, as well as screening. When our team suggest commercial micro pile installation or commercial helical pile installation, our experts are certainly not just opting for an architectural body, our experts are opting for a method that reduces danger at each step.

Micropiles use turning boring with a steel core as well as, normally, pressure-grouted connects right into competent strata. They do work in virtually any kind of dirt profile and also through blockages. Helical piles use a helix-bearing element that screws in to the soil to a torque-correlated ability, no cement called for for the most part. Helical tieback anchors provide lateral capacity for basement wall surfaces and also shoring without the surprise of percussion tools.

Both bodies prevent huge percussive electricity. When you tune the rotation rate and press force, as well as you maintain the tool sharp, the end result is actually a reduced, consistent hum instead of a hammer's staccato.

Micropiles versus helical piles: where each shines

Micropiles are actually the Swiss Army knife of deep foundation repair. They excel in mixed stuffing, metropolitan junk geography, and internet sites along with above constraints. Because they count on connect worry within cement and also rock or even tense soils, they can build higher capacities in a tiny impact. Our team have forced solitary micropiles to 200 to 400 kips in rock in the Northeast with 7 to 9 inch rotary tool gaps and also # 14 to 3-inch pubs or studying primaries. Where corrosivity is actually high, double oxidation security components matches easily into basic strategy. In deep foundation repair of famous frameworks, micropiles serpent with basement slabs and derive walls with minimal settlement risk.

Helical heaps flourish in cohesive grounds, timeworn profile pages, as well as sands that give trustworthy coil bearing. For commercial foundation stabilization on occupied sites, helicals rate manufacturing because they perform not need to have grout healing. Torque size throughout setup offers real-time quality control. With the right helix setup, capacities of 50 to 150 kips every stack are common, and also higher loads are actually possible along with larger shafts as well as multi-helix leads. When lateral tons or wall help are entailed, commercial helical tieback anchor installation addresses the trouble without vibration.

The crossover region is genuine. On a work with adjustable loads over frosty till, our experts might put helicals into the till and change to micropiles where patches or clutter produce rejection. If the schedule reprimands moist business, helicals typically gain. If the owner really wants the greatest capacity every component, or where bedrock is accessible, micropiles take the lead.

Noise and also vibration virtual: exactly how reduced can easily you go?

On an energetic hospital development, our experts put up 180 micropiles under a brand-new add-on while PICU bedrooms remained one floor away. The requirements minimal height particle velocity to 0.08 in/s at the existing design. Our team used a little electric drill gear, rotary down-the-hole without sky hammer, 4.5-inch cutter scalps tipped to 7 ins, as well as tension grouted at 250 to 300 psi. Vibration tracks remained peaceful, even when our company cored with aged groundwork rubble. The loudest moments were actually concrete saw hairstyles at the piece edges, which the manager booked around nap opportunities. That job educated me that the gear option and tooling matter as much as the foundation type.

For a record facility retrofit on retractable stuffing, our team made use of helical piles along with 1.75-inch square rays and also 10-12-14 inch helix arrangements. Installation torque averaged 6 to 8 kip-feet, correlating to load of 60 to 80 kips. The practice motors performed at informal levels. We stopped during the course of essential web server cutovers, after that returned to without penalty because helicals lug tons immediately. No curing problems, no cement distribution weaving by means of an active site.

Equipment as well as accessibility: what matches with the door wins

Noise- and also vibration-sensitive usually means access-sensitive. Our team routinely stage set through 36-inch doors and also merchandise elevators. A micropile gear can evaluate as low as 3,000 to 8,000 pounds and break down right into parts to relocate parts. Electric or diesel-electric crossbreeds cut noise better. Spoils are actually very little, usually a damp slurry that we accumulate for disposal, often a handful of cubic lawns complete for dozens of piles.

Helical heap setup prefers even lighter gear. A 10,000 to 12,000-pound gas excavator with a torque electric motor and also pole may operate in a garage bay. On smaller abilities, a skid-steer along with an earthly travel system runs silently enough that discussion lingers pair of gulfs over. If you need to have to slip inside, modular mast bodies position to a compact base and operate on power ride. The lack of grout implies no pipes crossing corridors as well as no washout mess.

Capacity, screening, and also QA without the racket

Both systems give reliable area verification without impact.

- Static tons screening: Our company have carried out 2 to 3 times working load examinations on micropiles and helical piles with hydraulic ports and also response frameworks that run silently. In medical facilities, we book examinations during low-occupancy hrs, however the hydraulic pumps are the loudest factor, certainly not the piles.

- Torque relationship for helicals: The relationship between installment twist and capability provides constant reviews. It is certainly not a substitute for proof exams, however it regulates development piles effectively.

- Grout stress logs for micropiles: Our experts document pressure and quantity to verify connection zone growth. On rock outlets, we keep an eye on profits and secure tensions that make sure close call without fracturing the rock.

For sidewise job, helical tieback anchors are actually evidence assessed to a lock-off lots. The examination is step-by-step as well as soundless aside from the pump. Tieback anchors can easily handle basement walls and also diggings while the road or building backing remains undisturbed.

Where steered stacks battle and also pierced shafts make excessive noise

Driven steel or even precast stacks carry impact hammers and vibratory motorists that disseminate via ground as well as structure. Even with vibrodrivers at low bigness, our experts have actually viewed hassle alarms at 200 feet. Drilled shafts can be silent, yet large augers and also center barrels demand cranes as well as higher clearance, as well as the spoils monitoring acquires disorganized quickly. If you are actually threading a brand new groundwork device through an active property, micropiles or even helical piles usually offer the right mix of low disruption and also constructability.

Design particulars that produce the difference

The best outcomes come from tailoring the structure to the constraints you really have, not the ones your standard spec assumes.

For micropiles, our company design connection lengths to sit in proficient product with traditional connection worries, frequently 80 to 200 psi in dirts and also 200 to 400 psi in rock, depending on site-specific exams. Our team select canvassing where the near-surface dirts are poor or even where sidewise tons concern. The steel primary may be a bar or even a smaller sized inner case. In harsh atmospheres, double rust protection is actually effortless to carry out. When groundwork, our team position braces that pick up the existing foundation with ports, preload if resolution is actually an issue, and then lock off.

For helical piles, our team select coil dimensions and space to avoid trailing results as well as guarantee each helix remains in skilled soil. The lead section might hold two or 3 coils, along with expansions contributed to reach out to aim at torque. In clay-baseds, our company as if to stay clear of quick development that buffs the ground, an usual newbie mistake that synthetically increases twist but decreases capability. In sands, our team watch opening pressure disorders and advance continuously to prevent disturbance.

Tieback anchors adhere to similar reasoning. A helical tieback anchor that lugs basement walls have to build adequate unbonded size behind the energetic wedge, then a helical-bearing sector for ability. Our experts usually proof exam to 120 to 150 per-cent of design load as well as lock off at working lots. Keeping track of wall motion validates performance.

Managing blockages, utilities, and also what you may certainly not see

In outdated areas, you teach blind if you do certainly not examine. Ground-penetrating radar as well as cautious as-built evaluation are actually necessary. Micropiles eliminate blockages far better than helicals given that our team may primary by means of block, concrete, and even little boulders with the appropriate littles. If our company reached a sizable obstacle that our team can easily not penetrate, our team counter the heap or change the pattern. For helicals, rejection on clutter demands moving or even predrilling a short pilot to clear the path, however predrilling need to be sized as well as executed to maintain dirt strength.

Utility corridors make complex everything. Small rigs as well as versatile formats aid interweave in between product lines. Our experts maintain balanced out resistances tight, generally within an inch or more for micropiles utilizing a pole along with a crowd system. Helicals remain accurate with correct resources and bandaging at start-up. A mindful layout keeps you away from avenues and also permits field changes without dropping the grid.

Construction sequencing in occupied buildings

Owners respect when they experience the job. Productive sequencing and also interaction protect against surprises.

We usually begin with an exhibition stack or a brief examination plan to affirm sound and also resonance levels. Tracking units happen beginning. As soon as the stakeholders view that the guideline stores, production ends up being regular. In health care environments, our experts collaborate with the custody registered nurse daily. We shut down in the course of medicine pass or even image resolution. On a gallery task, our experts quit during docent trips and overcame lunch to remain on schedule. Along with helicals, the absence of wet trade actions turns setting up in to a simple dancing. Along with micropiles, our experts rate around grout batching and also treating, yet the rhythm is predictable.

Foundation crack repair and when piles go into the picture

Foundation gap repair service alone seldom handles structural motion in smooth or adjustable soils. If the splits note negotiation or birthing failure, we maintain first. That is actually where commercial foundation repair couple with stacks. Our company found the foundation along with micropiles or even helical piles, lift if feasible, then restore splits along with epoxy injection Resistance Pile Installation or even stonework restores. The series matters. Fixing the gap and painting over the cause welcomes a 2nd round.

For structural foundation repair on an industrial slab that broke under a brand-new technical line, our experts put up helical piles through piece penetrations, linked them to a brand-new grade beam, and also took load with modifiable braces. Simply after bunch transmission performed the fracture repair service move on. Lifting was a matter of fractions of an in, done in increases while the manager checked out the machinery. No noise criticisms, as well as the line started on time.

Cost and routine realities

Neither micropiles neither helicals are the most cost effective method to put a structure on the ground if you have a clear internet site and no neighbors. They are actually the least expensive means to place a property on the ground when you have to function gently, inside, or inches from vulnerable occupants.

Micropiles usually tend to run greater per unit because of steel and also cement, however the capacity every pile may decrease count. Development fees range coming from 6 to 15 piles daily with a tiny gear, depending on deepness as well as geography. In stone, expect less each day however greater capacities. Helical piles frequently outpace that, with 10 to 25 daily typical in moderate depths, and they lug tons immediately. The most ideal expense management comes from exam information that permits the engineer tune connection durations, coil configurations, as well as approval criteria to real ground conditions, not worst-case guesses.

Environmental as well as logistic conveniences managers notice

Micropiles generate moderate spoils. In sensitive interiors, we record come backs, filter, as well as haul off in drums. Helical piles generate none. Less vehicles in and out lessens visibility for a busy facility. Sound stays low without a generator ranch or even compressors for hammers. On one public library project, our company maintained ambient noise listed below 70 dBA at 25 shoes coming from the rig utilizing an electricity motor and also rubber mats under organized steel. Staff shelved manuals while we put in piles in the basement.

The carbon dioxide profile may choose these devices also. Smaller devices, fewer shippings, as well as efficient steel use made up for cement in cement for micropiles. Helicals stay clear of cement totally unless pointed out along with grout columns or even encasements.

Integrating along with shoring and excavation

Basement developments as well as walk-out add-ons typically mix founding along with temporary shoring. Helical anchors as well as protection heaps participate in effectively together. A contractor may put up helical anchors for lateral support of a soldier-pile wall, then make use of vertical helical piles or resistance heaps for the brand new ground. Commercial resistance pile installation along with jack-driven steel piles can also function quietly in the ideal dirts, particularly for founding where upright area is actually limited. The usual string is soundless hoisting or turning rather than hammering.

Tieback supports are entitled to a details on building closeness. In tight city whole lots, are sure the easement responsible for the wall permits unbonded duration as well as helix area. Our team have settled this along with staged boring from inside the home, tilted low, and utilizing briefer unbonded spans that align with a more thick wall surface as well as even more supports. It is a geometry concern with efficient constraints, not a factor to go back to loud methods.

When not to use micropiles or even helicals

There are actually advantage situations. Really dense crushed rock with sizable cobbles may annoy helical pile advancement, despite threatening coil reducing sides. If predrilling concessions bearing, the benefit disappears. Micropiles through very retractable loess could be difficult without careful boring liquid command, due to the fact that the hole may neck or slough and also lessen connection. Where uplift regulates and also deterioration risk is excessive, equipment security might drive prices up unless you utilize stainless or HDPE-sheathed components. In marine regions with search, outlining for sidewise stability concerns, and in some cases punched shafts with cages still make additional sense if you may isolate the work.

If the only gain access to is actually through a stairwell along with 200-pound restrictions, even the tiniest gears might not pass. Then the solution turns to bracketed resistance heaps utilizing hand-portable pushes or even imaginative holding that the building engineer should take. Opinion concerns. The quietest option is actually the one you may actually build.

The part of preconstruction testing

On quiet sites, a short exam program repays. For micropiles, a preliminary exam heap program confirms bond tension in each stratum. In split dirts, we often mark two or even 3 applicant connection horizons and examination to find which delivers foreseeable behavior along with satisfactory stress as well as yields. For helicals, a couple of preproduction piles give you torque-to-capacity relationships specific to the soil, validated through evidence exams. On a museum annex, 3 helical test stacks saved pair of coil plates every pile throughout the work, cutting expense and also bring in creation faster.

Owners like information. Resonance standard readings prior to job starts produce a referral. If an alert activates, you can reveal an opportunity history along with clear signatures as well as change in real time. It is actually rare to stop turning installation because the method is inherently stable, but alerts always keep everybody sincere and also confident.

Choosing a companion for peaceful work

The specialist's shop matters as much as the designer's particulars. Seek a workers that can show current commercial foundation repair work in occupied properties and deep foundation repair around delicate possessions. They should possess or gain access to electrical or hybrid rigs, have a plan for spoils restriction, and bring calibrated torque drives. Ask to find machinery records from prior commercial helical pile installation as well as micropile installation jobs. If they can certainly not make cool files, they will certainly certainly not make a peaceful site either.

When wall structures need lateral support, make certain the exact same crew is comfortable along with helical anchors and tieback anchors, plus wall structure layers as well as waler units that fit your geometry. Balance ends up being straightforward when one subcontractor manages the upright and also sidewise bodies together.

A practical comparison for selection makers

Here is the quick version field staffs make use of when deciding on between bodies in tight, silent setups:

- Micropiles: Finest in mixed or impaired dirts, via old foundations, to rock, and also for the highest capacities per aspect. Low vibration boring, reasonable spoils, cement strategies called for, urgent or next-day bunch transfer depending on spec. Ideal for structural foundation repair as well as groundwork where you need predictable actions via just about anything the urban area threw in the ground.

- Helical heaps: Finest in logical grounds and sands along with reliable bearing. Fast, clean, and also right away loadable. Twist offers continuous QA. Pair typically with helical tieback anchors for lateral assistance. A tough choice for commercial foundation stabilization inside active properties as well as routines that punish wet trades.

Bringing it together on true projects

A historical theater makeover in a heavy midtown asked for brand-new column lots beside a delicate plaster proscenium. Our team utilized micropiles for the new pillars given that the profile page varied filler, sand, and also shallow shale. The exploration gear tucked right into the orchestra pit and also worked with two weeks with the concourse open above. Vibration keeps track of never ever tripped.

Two months eventually, on a strategies stockroom growth near an online rail impulse, helical piles supported a brand new canopy. The monitor owner demanded an online resonance limitation, and the professional kept job between learn windows. Torque complied with targets, proof tests passed, as well as the owner packed the piles as soon as the waler steel cooled down coming from welding.

Both jobs stayed away from the noise as well as shock of driven work. Each met cramping timetables. Neither will have succeeded without systems that recognize their neighbors.

Final advice for staffs intending quiet foundations

If you take absolutely nothing else: match the foundation to the sensitiveness and the dirt, certainly not to routine. Early geotechnical input, a portable rig planning, and also a quick, focused test course will certainly keep you away from issue. Paper whatever. Build a pattern that recognizes silent hours and also gives the crew expected rhythms. For foundation crack repair tied to negotiation, maintain first along with a strong body, then resolve the fractures so they carry out certainly not return.

Noise- and vibration-sensitive internet sites reward silent tools and also self-displined strategy. Micropiles and also helical piles provide each. When the restraints stack up, these bodies permit you create where others can easily certainly not, and also they perform it along with a hum rather than a hammer.

UNITED STRUCTURAL SYSTEMS OF ILLINOIS, INC

2124 Stonington Ave Hoffman Estates, IL 60169 847-382-2882 [email protected]> Mon-Fri 8:30am-5:00pm Sat-Sun By Appointment