Emergency Boiler Repair: How to Handle Repeated Lockouts

Heating systems don’t fail on a sunny afternoon in May. They falter at 6:30 a.m., frost on the inside of the kitchen window, the family due back from holiday, or an elderly relative downstairs with the electric heater already tripping the sockets. Repeated boiler lockouts turn a cold morning into an emergency fast. The good news is that a lockout is a protective response, not a catastrophe. The boiler is telling you something is wrong, then shutting itself down to stay safe. If you know how to read the signs, you can protect the system, keep occupants safe, and restore heat with minimal drama.

I’ve spent years on call for local emergency boiler repair, much of it covering same day boiler repair requests, and the pattern with lockouts is consistent. The fault is often simple once you trace it, but finding the root cause takes a clear head and a methodical approach. This guide sets out how to handle repeated lockouts, from the first checks a householder can make to the deeper diagnostics a qualified boiler engineer will carry out. If you’re in Leicester or nearby, the specifics apply just the same, though you’ll see me note a few local quirks from boiler repair Leicester callouts, including hard water scaling and seasonal flue issues.

What a lockout really is

A modern gas boiler monitors its own operation constantly. When the control board detects a condition outside the safe operating window, it locks the appliance out. Think of it as a seatbelt locking during a sudden stop. The flame sensor does not see flame when it should, the temperature sensor sees a spike, the pressure sensor reports too low or too high a reading, or the flue thermostat registers excessive heat because gases are not escaping. The board then cuts off ignition, often leaving an error code on the display. Repeated lockouts mean that either a temporary fault keeps recurring or a reset is clearing the symptom without addressing the cause.

The common triggers by category are fuel and ignition problems, water circulation problems, safety sensor trips, exhaust and combustion air problems, and control or wiring issues. Each category has different fingerprints. A competent diagnosis follows those trails systematically, because changing parts at random only burns money and often masks the real problem for a week or two before it returns.

Safety first, then information

If you smell gas, if you hear an unusual hissing, or if a carbon monoxide alarm is sounding, do not attempt resets or DIY. Turn off the boiler, open windows, leave the property, and call the gas emergency number for your area. For non-emergency lockouts, make the system safe by isolating the power at the spur, let the unit cool for at least 5 to 10 minutes, then restore power and read the boiler display. Many models will show a fault code such as F.28, F.75, L2, E133, or similar. Note that code, any lights flashing on the front panel, and what you observe in the first minute after a reset attempt. If you are seeking urgent boiler repair, this information speeds up the fix.

I advise clients to keep a simple log: date, time, what the boiler showed, any noises, the pressure gauge reading, and the outdoor conditions. Two days of notes often save two hours on site.

Resetting without making things worse

A reset is not a cure, it is a diagnostic step. If the boiler locks out once per winter when a strong gust blows down the flue, a single reset is reasonable. If it locks out twice in a day, the system needs attention. The control panel reset button or menu entry is plainly marked on most units. Press it once, then watch and listen. Does the fan start? Do you hear clicking as the ignition spark fires? Does the flame light then die? Do you hear surging water or kettling sounds? Does the pressure gauge drop or spike? These are the signals that tell a trained ear where to look.

I’ve seen homeowners perform ten resets in ten minutes. That is a quick way to flood the condense trap, overheat the heat exchanger, or trip additional safety devices. Give it one measured attempt. If it fails again, stop and call a professional for same day boiler repair if you have no heat or hot water.

The fingerprints of the main fault groups

Fuel and ignition issues show up as repeated failed starts. The fan runs, the ignition clicks, the gas valve opens, but the flame does not establish or the flame sensor fails to prove it. You’ll hear click, click, click, then a lockout code that often references ignition failure. On many brands, this points toward problems like low gas pressure at the appliance, a partially blocked injector, a dirty flame rectification electrode, a cracked HT lead, or a gas valve coil that measures within spec cold but fails when hot. In Leicester I see cases in older terraces where meter governors are slow to open in very cold weather. You get a morning lockout, then it runs all day. That’s a clue to external supply and regulator behavior.

Water circulation faults produce different sounds. You may hear bubbling, a short whoosh, then silence as the limit thermostat trips. The display might show overheat or a pump error. Often the system pressure sits low, under 1.0 bar cold, or drops quickly during operation. A seized pump, a pump impeller clogged with magnetite, or air locked radiators can all cause the heat exchanger to overheat locally, triggering a safety trip and lockout. Households with open-vented systems converted to sealed without adequate flushing are especially prone. Repeated lockouts overnight followed by longer run times after bleeding radiators is a giveaway.

Flue and combustion air problems are trickier because they are environmental as much as mechanical. A flue partially blocked by nesting material, leaves, or snow can cause intermittent pressure switch faults. A poorly sealed flue can cause wind-related downdrafts that extinguish the flame. Short flue runs on coastal or exposed sites are notorious for this on certain models. Once in a block of flats, the only symptom was a lockout when someone on the floor below ran a powerful cooker hood that altered internal air pressure. If your boiler sits in a tight cupboard with minimal ventilation, lockouts during long showers can be a sign of inadequate air supply.

Control and wiring issues tend to be less dramatic. The boiler may heat when you manually demand via the panel but lockout when a smart thermostat calls for heat. Low voltage supply ripples, miswired external controls, or a damp junction box can trip faults that look like internal failures. I’ve had two callouts where the real culprit was a corroded earth bond. The flame rectification sensor relies on a good earth reference. A poor earth confuses the brain, and the board declares flame loss.

Finally, condensate problems are a classic source of repeated lockouts in winter. A partially frozen external condensate pipe restricts flow, the condensate traps back up, and a switch tells the board to shut down. Fifteen minutes later, it thaws and runs for an hour, then freezes again at dusk. If the boiler sits in a loft, the run might be longer and less insulated, making the problem more pronounced. This is where a simple upgrade to a larger-bore, well-insulated condensate run solves the issue for good.

What the pressure gauge is telling you

A healthy sealed system sits around 1.0 to 1.5 bar cold and rises by 0.2 to 0.5 bar as it heats. Repeated lockouts with a gauge that sits at zero suggest a loss of water, a failed filling loop left closed, or a pressure sensor defect. If you top up to 1.5 bar and it drops back to 0.5 bar within hours, you likely have a leak or a failed expansion vessel. That vessel is the small tank with a diaphragm inside, charged with air or nitrogen. If it loses charge, the pressure swings become wild. The boiler might hit 3.0 bar hot and lift the pressure relief valve, dumping water, then sit at 0.3 bar cold the next morning, and lock out. People chase leaks that do not exist because the vessel cannot absorb expansion any longer. On site, a local boiler engineer will check the precharge with a gauge, restore it to spec, and check the PRV for seating after it has lifted. Many PRVs never seal perfectly once opened, so keep an eye on the discharge outside.

Reading and using fault codes the right way

Fault codes are a starting point, not a verdict. F.28 might mean ignition failure, but I have replaced more flame electrodes for ignition faults caused by gas valves than I care to admit. The right move is to confirm combustion, gas supply, and the health of the ignition circuit before changing anything. The code narrows the search, then you verify with tests. At a minimum, confirm that:

-

The appliance has correct gas supply at working pressure, under full load. Do not judge by smell or by a single reading at the meter with everything else off.

-

The condensate path is free, the trap is clear, and any external run is clean, appropriately sized, and insulated if required.

These two checks alone resolve a surprising portion of repeat lockout calls, especially in winter when urgent boiler repair requests spike and small faults compound.

Hard water, soft faults

Leicester and much of the East Midlands have moderately hard to hard water. You see it on kettle elements, and you see it inside boilers. Scale builds up on the hot side of the primary heat exchanger, creating hotspots that trip the high limit. The sound is unmistakable, a rattly kettling that gets worse at higher flow temperatures. On combi boilers, a scaled domestic hot water plate heat exchanger can reduce flow and cause the boiler to cycle rapidly, which sometimes presents as a lockout during long showers. If your radiators are hot but hot water is inconsistent, think plate heat exchanger. If both heating and hot water cause overheat, think primary side scale or poor circulation.

In practice, we measure differential temperatures, check pump duty, and look for telltale temperature spikes on the display during demand. A chemical clean, a new plate heat exchanger, or a power flush with inhibitor can return the system to stable operation. The marketing promise of a “one-hour fix” rarely applies here, but within a same day boiler repair window, a temporary restore with adjusted flow temperature and a scheduled clean the next day keeps the house warm.

Don’t overlook the basics when the weather turns

Cold snaps reveal weaknesses. A few examples from recent winters:

A semi-detached with a 22 mm condensate run outside, uninsulated. At minus 4 Celsius it froze into a solid column, tripping the boiler every two hours. Wrapping the pipe might have prevented it, but the right fix was rerouting most of the run internally, upsizing to 32 mm where exposed, and adding an insulation sleeve. The house went from repeated lockouts to trouble-free for the rest of the season.

A top-floor flat with a long horizontal flue run and a tall external terminal facing west. On windy nights, the boiler would lock out mid-cycle. The cure was a correctly specified plume management kit and terminal, verified flue falls, and a check of all joints for leaks. We also tightened the cupboard ventilation as per the manufacturer’s guidance, reducing the pressure differential that aggravated the issue.

A family home with a modern condensing combi and a smart thermostat set to aggressive energy-saving schedules. The system would drop to 12 Celsius overnight, then call for 21. The boiler ran flat out, hit limit quickly in magnetite-choked radiators, and locked out. After a dose of system cleaner, a flush, fresh inhibitor, and a thermostat schedule that staged up temperatures, the lockouts stopped.

These are not exotic problems. They reflect the simple truth that a boiler is one part of a system. Repeated lockouts are often a symptom of an imbalance or a restriction elsewhere, not a failed boiler component.

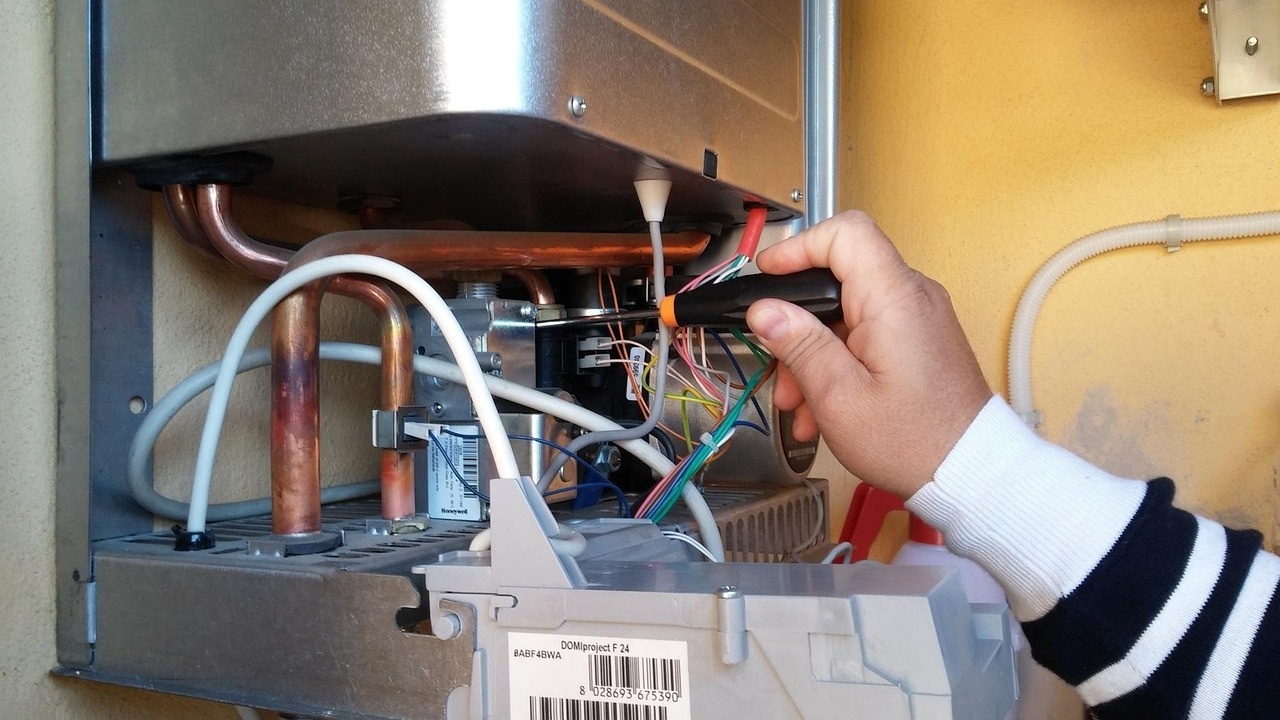

How a professional finds the root cause

When you call for local emergency boiler repair, the first job is to reproduce the fault in a controlled way. The steps below are typical, tailored to the make and model:

Visual inspection. Look for scorch marks, water staining, kinked or sagging flue sections, signs of previous leaks at pump seals, and evidence of inhibitor or lack of it. Check the condensate trap and line for debris, backfall, or ice. Verify isolation valves are fully open.

Electrical checks. Confirm correct polarity, voltage at the board, and a sound earth. Measure continuity on key sensors. Test the electrode lead and ignition transformer output. Inspect connectors for oxidation. Many intermittent lockouts begin with a loose Molex plug.

Gas experienced boiler engineer services checks. Conduct tightness testing if needed, then measure standing and working pressure. Confirm correct inlet pressure at the appliance while the burner is at maximum rate. Compare to manufacturer specs. If pressure sags when other appliances run, it could be a regulator or pipe sizing issue.

Combustion analysis. Use a calibrated flue gas analyzer to check CO and CO2 against manufacturer specifications. An unhealthy flue reading indicates burner, gas valve, or air mix issues and may coincide with lockouts due to flame loss. Do not tune by ear or by color of flame.

Hydronic checks. Assess system pressure behavior cold and hot, expansion vessel precharge, pump performance, and temperature differentials across the heat exchanger and key radiators. Look for rapid spikes that trigger the limit stat.

Functional testing. Observe a complete start cycle: fan purge, ignition, flame establishment, modulation, and stop. Note exactly when and why the lockout occurs. Cross-reference the timing to the code and the signals from sensors.

Once you have data, the solution is usually straightforward, whether that is clearing a blocked condensate, replacing a cracked electrode, recharging a vessel, renewing a pump head, or correcting a flue fall. The art lies in knowing what not to change. Boards and gas valves are expensive. In my practice, replacing either without conclusive tests is a last resort.

When repair becomes replacement

No one likes to hear it, but sometimes the right call is to stop chasing faults on a boiler at the end of its life. If the unit is beyond 12 to 15 years old, spares are scarce, and the primary heat exchanger is scaled or leaking, the cumulative cost of gas boiler repair over one or two winters can exceed the price of a new, efficient boiler with a solid warranty. Repeated lockouts due to progressive corrosion, blocked waterways, and degraded sensors point to systemic wear.

The triggers that move the needle toward replacement include metal fatigue in the heat exchanger, flue systems no longer compliant with current standards, repeated board failures due to moisture ingress in a case that no longer seals, and overall poor efficiency that inflates gas bills. Households often see a 10 to 20 percent energy reduction with a modern condensing unit compared with a tired older boiler. If you are already spending on urgent boiler repair twice a season, a planned upgrade avoids the 8 p.m. scramble on a freezing night.

What homeowners can sensibly do before calling

There are a few safe checks you can make that sometimes restore operation long enough to wait for a scheduled visit rather than an out-of-hours call:

Check system pressure. If the gauge reads below 1.0 bar when cold, consult your manual on topping up via the filling loop to 1.2 to 1.5 bar. If it drops quickly again, stop topping up and call a boiler engineer. Constant top-ups add oxygen and accelerate corrosion.

Check the condensate outlet. If the external condensate pipe is visibly frozen or dripping slowly, thaw it gently with warm towels or a hot water bottle, never with a blowtorch. Insulate it if possible. If you cannot access it safely, wait for help.

Bleed trapped air. If radiators are gurgling and the top is cold, bleeding a small amount of air may improve circulation. Remember to recheck system pressure afterward.

Power cycle once. Turn off the boiler and the fused spur, wait five minutes, then power back on and attempt a single reset. Note any codes or noises.

Verify controls. Ensure the room thermostat is calling for heat and that the boiler timer is set correctly. A flat thermostat battery has duped many into thinking they had a boiler fault.

If these do not help or the boiler locks out again, do not persist. The priority is to avoid turning a small issue into an expensive one. For households in the area, searching boiler repairs Leicester or gas boiler repair near me will surface local boiler engineers who can attend quickly. Many offer boiler repair same day during peak winter.

Why repeated lockouts matter beyond inconvenience

Every lockout is a wear event. Ignition cycles stress electrodes and transformers. Overheats stress seals. Rapid pressure swings stress the pressure relief valve and the expansion vessel. The cost is not only discomfort but accelerated component fatigue. There is also a safety dimension. A boiler that frequently loses flame may be tolerating marginal combustion. Carbon monoxide risk remains low if the appliance is correctly sealed and vented, but it creeps upward when faults go unaddressed. An annual service is not a luxury. It is the cheapest insurance for steady, efficient operation. When I perform services after a winter of lockouts, I typically find one or more of the following: electrodes out of spec by a millimeter, condensate traps half full of debris, filters choked with magnetite, combustion slightly off the manufacturer’s numbers, or a vessel down to half its charge. Fix them early, avoid the emergency.

The Leicester particulars: water, wind, and housing stock

Local conditions shape faults. The Leicester area’s water hardness ranges from about 140 to 300 ppm as calcium carbonate depending on supply zone. I see more plate heat exchanger scaling on combis in those areas than in softer water regions. In city terraces, external condensate runs often snake under yard flags then up to a stack. Those go first when the temperature drops. Repeated lockouts after sundown in November often trace back to those runs.

Wind exposure matters on certain post-war estates with gable-end flue terminals. A flue that meets the letter of the installation manual can still underperform when a prevailing westerly loads it. In those cases, a revised terminal or plume kit fitted by local boiler engineers who know the estate’s quirks often ends the lockouts. Housing stock with microbore pipework amplifies circulation issues. A tiny bit of sludge, and your pump struggles. If you own such a property and see an overheat lockout after long calls for heat, think sludge and flow restriction long before you urgent gas boiler repair think board failure.

What good service looks like in an emergency

When you call for local emergency boiler repair, the difference between a vendor and a professional is process. You should hear a few key questions right away: fault code, pressure reading, whether hot water demand behaves differently from heating demand, any recent work on the system, and any visible leaks. The engineer should arrive with calibration certificates for combustion analyzers, common spares for your model, and the right test gear. A thorough job results in a plain-English explanation of the cause, the steps taken, any risks, and any recommended follow-up. If a same day boiler repair is possible, you will expert boiler repair services Leicester get heat restored and a plan for any deeper system work, such as a flush or a vessel replacement, at a sensible time.

From a cost perspective, transparency matters. A fixed call-out plus labor, clear parts pricing, and no surprise “board first” policy builds trust. Engineers who jump straight to expensive components without numbers from a meter or analyzer are guessing with your money. Ask for readings: gas inlet kPa with burner on, CO and CO2 percentages post-adjustment compared to the manufacturer’s data plate, expansion vessel precharge measured, and delta-T across the heat exchanger. These are not trade secrets. They are basic quality checks.

Preventing the next lockout

Once the heat is back, take the opportunity to improve the system. Fit a magnetic filter on the return if you do not have one. Flush or at least dose with a cleaner and replace with fresh inhibitor. If you have repeated condensate freezing, reroute and upsize the line. If the expansion vessel was down, schedule a recheck in six months. If your thermostat causes aggressive cycling, tune the settings to stage setpoint increases and extend minimum on-times. A modest weather compensation curve on a compatible boiler can transform stability, preventing overshoots and trips.

Make annual servicing more than a stamp in a book. Ask for a combustion analysis printout, confirmation of gas rate, electrode gap check, condensate trap clean, burner seal inspection where applicable, and verification of system water quality. Over time, you will see trends and catch issues before they cause a lockout.

A few cases that teach the right lessons

A landlord rang late on a Sunday. The tenant reported three lockouts that day. The display said E133, an ignition fault on that brand. The last engineer had fitted a new electrode the month before. On site, working pressure at the appliance dipped from 21 mbar to 14 mbar when the cooker and fire also ran. That value sat outside the appliance spec. The cure was not in the boiler at all. The meter governor had gone lazy. Gas supplier replaced it. No more lockouts. The lesson: measure under load.

A family in winter reported lockouts only when hot water was used back-to-back for showers. Heating alone was fine. The boiler would light for hot water, temperature would rocket, then trip. Differential across the plate heat exchanger was excessive, indicating scale. After cleaning and then replacing the plate, hot water stabilized and the lockouts disappeared. The lesson: demand mode matters, and hot water faults can be distinct from heating faults on a combi.

An elderly couple saw repeated overheat lockouts despite system pressure at 1.2 bar. Radiators were warm at the bottom and cold at the top. The pump had been replaced six months earlier. On inspection, the microbore system was heavy with magnetite. The pump was fine, but the flow paths were partially blocked. A thorough chemical clean and power flush with a magnetic filter fitted afterward restored circulation. The lockouts ended. The lesson: do not assume new means good, and water quality is a first-class citizen.

When and how to escalate for help

If you have no heat and a vulnerable person in the home, or if temperatures are near freezing, treat repeated lockouts as an emergency. Many firms offering boiler repairs Leicester maintain a triage list in winter and can prioritize such calls for boiler repair same day. If you call, be ready with:

-

The make and model of the boiler, the fault code on the screen, and the current pressure reading.

-

Any work recently done on the heating system, such as radiator replacements, thermostat changes, or plumbing work near the boiler.

Providing those details helps the dispatcher assign the right person with the right parts. If you are calling after hours, a good local boiler engineer may offer a safe temporary restore while ordering the proper component for a next-day fit. That beats a generic “we’ll replace the board” approach every time.

Costs, expectations, and the value of doing it right

Emergency work costs more than scheduled service. Expect a call-out fee and hourly labor that reflects evening or weekend rates. The key to keeping the total reasonable is accuracy. A half-hour of careful testing is cheaper than a chain of misdiagnosed parts. A well-stocked van can shave hours off a repair. Experienced engineers carry common electrodes, sensors, condensate traps, pump heads, gas valves for popular models, and universal flue sensors, plus consumables like seals and inhibitor. That means a single visit often restores operation, even for urgent boiler repair requests.

For homeowners, the value calculation is simple. Address the causes of repeated lockouts promptly, invest in water same day service for boilers quality, keep the condensate path sound, and have the combustion checked annually. You are buying reliability and lower gas use, not just warmth tonight.

Final thoughts from the field

Boilers do not have personalities, but they do have histories. Each repeated lockout is a sentence in that history. If you read it, you will see patterns: winter downdrafts at the flue, pressure swings from a sleepy expansion vessel, temperature spikes from a scaled heat exchanger, or a faltering ignition under marginal gas supply. The correct response is less about heroics and more about paying attention, testing, and making small, permanent improvements. For those in and around Leicester, finding a responsive, reputable team for boiler repair Leicester work means you have someone who knows the local water, the local housing stock, and the little details that turn a system from temperamental to dependable. Keep their number handy for local emergency boiler repair, and do not wait for the next cold snap to sort out the small things. Your boiler will stay lit, your home will stay warm, and those lockouts will become a memory rather than a routine.

Local Plumber Leicester – Plumbing & Heating Experts

Covering Leicester | Oadby | Wigston | Loughborough | Market Harborough

0116 216 9098

[email protected]

www.localplumberleicester.co.uk

Local Plumber Leicester – Subs Plumbing & Heating Ltd deliver expert boiler repair services across Leicester and Leicestershire. Our fully qualified, Gas Safe registered engineers specialise in diagnosing faults, repairing breakdowns, and restoring heating systems quickly and safely. We work with all major boiler brands and offer 24/7 emergency callouts with no hidden charges. As a trusted, family-run business, we’re known for fast response times, transparent pricing, and 5-star customer care. Free quotes available across all residential boiler repair jobs.

Service Areas: Leicester, Oadby, Wigston, Blaby, Glenfield, Braunstone, Loughborough, Market Harborough, Syston, Thurmaston, Anstey, Countesthorpe, Enderby, Narborough, Great Glen, Fleckney, Rothley, Sileby, Mountsorrel, Evington, Aylestone, Clarendon Park, Stoneygate, Hamilton, Knighton, Cosby, Houghton on the Hill, Kibworth Harcourt, Whetstone, Thorpe Astley, Bushby and surrounding areas across Leicestershire.

Google Business Profile:

View on Google Search

About Subs Plumbing on Google Maps

Knowledge Graph

Latest Updates

Follow Local Plumber Leicester:

Facebook |

Instagram

![]()

Visit @subs_plumbing_and_heating on Instagram

Gas Safe Boiler Repairs across Leicester and Leicestershire – Local Plumber Leicester (Subs Plumbing & Heating Ltd) provide expert boiler fault diagnosis, emergency breakdown response, boiler servicing, and full boiler replacements. Whether it’s a leaking system or no heating, our trusted engineers deliver fast, affordable, and fully insured repairs for all major brands. We cover homes and rental properties across Leicester, ensuring reliable heating all year round.

❓

Q. How much should a boiler repair cost?

A. The cost of a boiler repair in the United Kingdom typically ranges from £100 to £400, depending on the complexity of the issue and the type of boiler. For minor repairs, such as a faulty thermostat or pressure issue, you might pay around £100 to £200, while more significant problems like a broken heat exchanger can cost upwards of £300. Always use a Gas Safe registered engineer for compliance and safety, and get multiple quotes to ensure fair pricing.

❓

Q. What are the signs of a faulty boiler?

A. Signs of a faulty boiler include unusual noises (banging or whistling), radiators not heating properly, low water pressure, or a sudden rise in energy bills. If the pilot light keeps going out or hot water supply is inconsistent, these are also red flags. Prompt attention can prevent bigger repairs—always contact a Gas Safe registered engineer for diagnosis and service.

❓

Q. Is it cheaper to repair or replace a boiler?

A. If your boiler is over 10 years old or repairs exceed £400, replacing it may be more cost-effective. New energy-efficient models can reduce heating bills by up to 30%. Boiler replacement typically costs between £1,500 and £3,000, including installation. A Gas Safe engineer can assess your boiler’s condition and advise accordingly.

❓

Q. Should a 20 year old boiler be replaced?

A. Yes, most boilers last 10–15 years, so a 20-year-old system is likely inefficient and at higher risk of failure. Replacing it could save up to £300 annually on energy bills. Newer boilers must meet UK energy performance standards, and installation by a Gas Safe registered engineer ensures legal compliance and safety.

❓

Q. What qualifications should I look for in a boiler repair technician in Leicester?

A. A qualified boiler technician should be Gas Safe registered. Additional credentials include NVQ Level 2 or 3 in Heating and Ventilating, and manufacturer-approved training for brands like Worcester Bosch or Ideal. Always ask for reviews, proof of certification, and a written quote before proceeding with any repair.

❓

Q. How long does a typical boiler repair take in the UK?

A. Most boiler repairs take 1 to 3 hours. Simple fixes like replacing a thermostat or pump are usually quicker, while more complex faults may take longer. Expect to pay £100–£300 depending on labour and parts. Always hire a Gas Safe registered engineer for legal and safety reasons.

❓

Q. Are there any government grants available for boiler repairs in Leicester?

A. Yes, schemes like the Energy Company Obligation (ECO) may provide grants for boiler repairs or replacements for low-income households. Local councils in Leicester may also offer energy-efficiency programmes. Visit the Leicester City Council website for eligibility details and speak with a registered installer for guidance.

❓

Q. What are the most common causes of boiler breakdowns in the UK?

A. Common causes include sludge build-up, worn components like the thermocouple or diverter valve, leaks, or pressure issues. Annual servicing (£70–£100) helps prevent breakdowns and ensures the system remains safe and efficient. Always use a Gas Safe engineer for repairs and servicing.

❓

Q. How can I maintain my boiler to prevent the need for repairs?

A. Schedule annual servicing with a Gas Safe engineer, check boiler pressure regularly (should be between 1–1.5 bar), and bleed radiators as needed. Keep the area around the boiler clear and monitor for strange noises or water leaks. Regular checks extend lifespan and ensure efficient performance.

❓

Q. What safety regulations should be followed when repairing a boiler?

A. All gas work in the UK must comply with the Gas Safety (Installation and Use) Regulations 1998. Repairs should only be performed by Gas Safe registered engineers. Annual servicing is also recommended to maintain safety, costing around £80–£120. Always verify the engineer's registration before allowing any work.

Local Area Information for Leicester, Leicestershire